Sintering Technology

What is Sintering:

Cobetter UHMWPE porous material’s primary structure is UHMWPE powder. A large number partially distributed micro-connected holes are generated during the sintering process, through which the porous material can be produced to satisfy various of different treatment process and special needs.

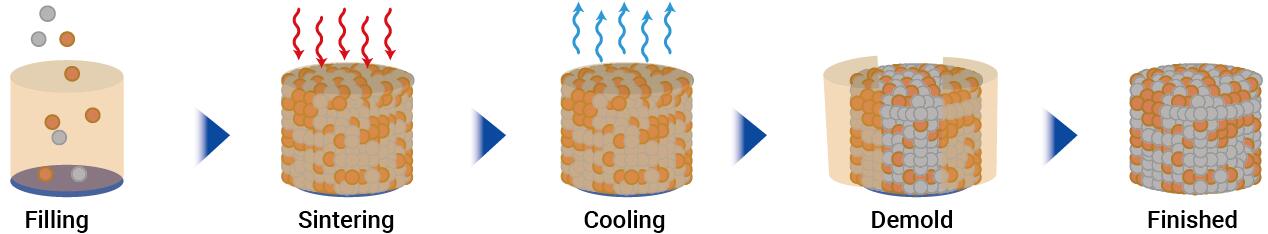

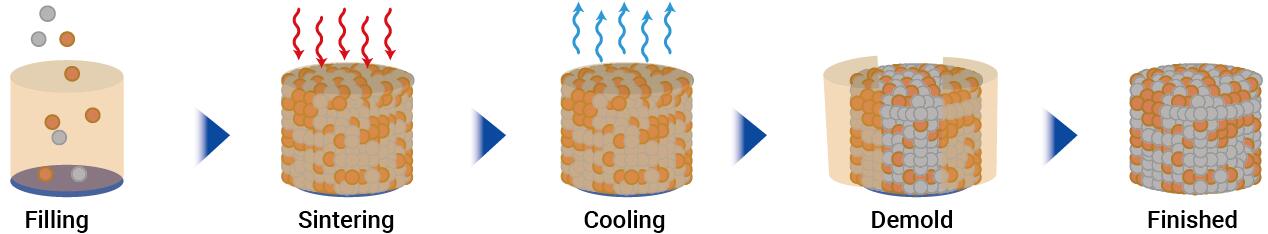

Cobetter owns the technology of particle pressed sintering, which means that we will mix the UHMWPE powder and then fill the mixed powder into a customized mold. During the process of filling mixed powder, we will also simultaneously use vibration technology to ensure the denseness of material. After that, the mould will be placed into the sintering fumace for firing under the setting time and temperature so that the powder particles only melt on the surface and bond together under the condition of incomplete melting. Through this process, the porous body consists of microscopic pores between particles and then finally the porous sintering material is completed.

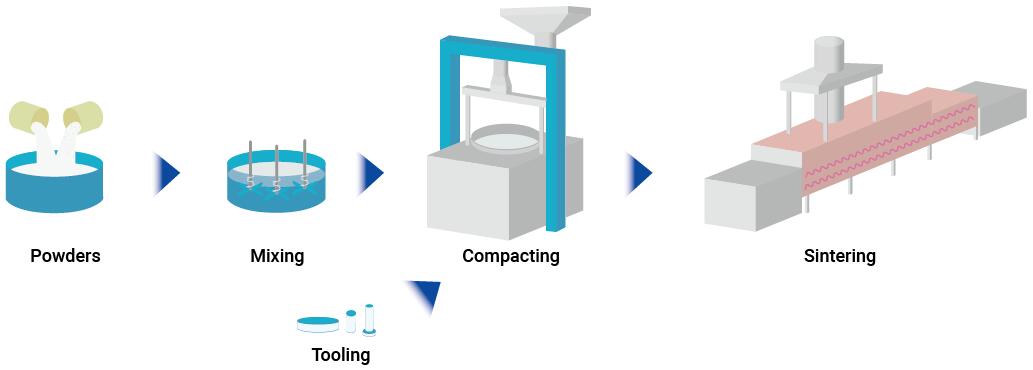

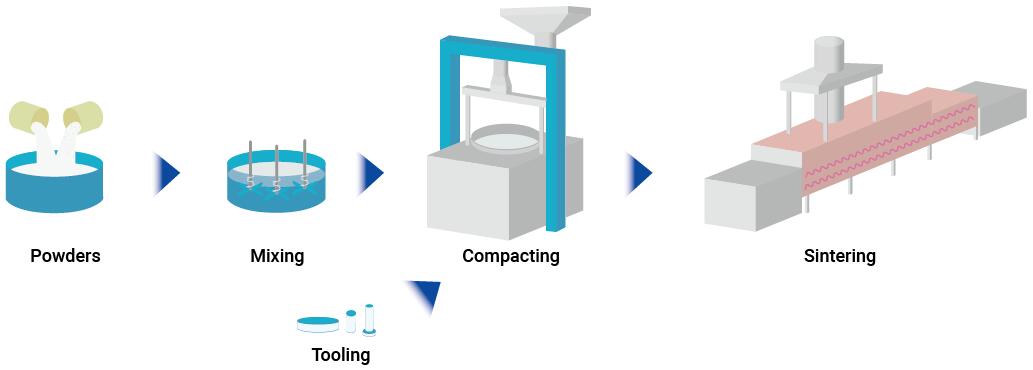

The technology process flow can be simplified into the following procedures:

Powder → Mixed Material (This step is required containing other ingredients) → Refilling → Vibrating → Sintering → Developing Mould → Final Product

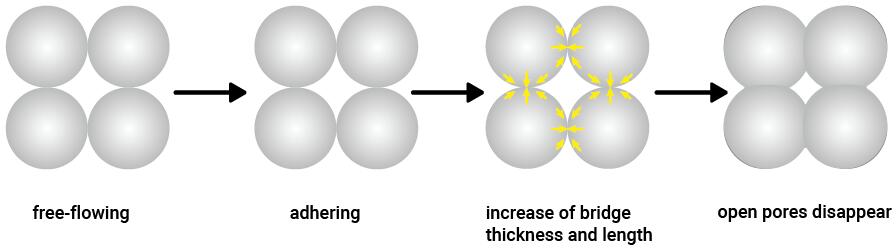

Sintering has three stages:

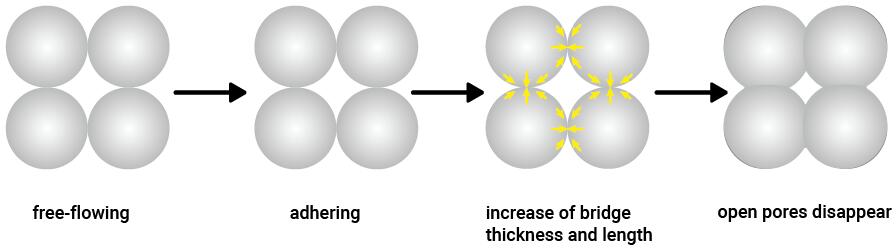

Early stage of sintering: The early stage of sintering is also called bonding stage. During this stage, the original contact point or contact surface is converted into crystalline bond, which means that the sintering neck will be generated through atom’s diffusion, nucleation, growth or the molecular migration process.

Middle stage of sintering: During the middle stage of sintering, the mass migration of atom or moleculars to particle bonding surface enlarges the sintering neck and decrease the space between particles so that the matrix powder forms a continous mesh. Meanwhile, the growth of crystal particle will cause the shrinkage of sintered body. The increase of matrix strength is the main characteristic during this stage.

Late stage of sintering: Late stage of sintering is also called pore spheroidization and shrinkage stages. During this stage, the pores of the matrix gradually become discontinuous, the pore shape tends to be spherical, and the pore size and the volume of the sintered body will shrink slowly.

Material Properties

UHMWPE is a linear polyethylene with an average molecular weight of more than 1.5 million and it has the similar molecular structure as ordinary polyethylene. The high molecular weight provides UHMWPE with outstanding properties that other engineering plastics cannot compare with, such as high impact resistance, abrasive resistance, self-lubricating property, corrosion resistance, low shock absorption energy and water absorption. UHMWPE has great corrosion resistance. Its abrasive resistance is 5.1 times higher than polytetrafluoroethylene (PTFE), and its adhesion resistance is second only to PTFE in engineering plastics. Additionally, UHMWPE also has good self-lubricity property and the friction coefficient is only 0.05-0.11. Moreover, UHMWPE’s chemical stability is very high. Except of oxidizing acid solution, it can withstand a variety of corrosive media such as acid, alkali, and salt and some organic media (except naphtaline solvent) in a certain temperature and concentration range. In addition, UHMWPE also has great mechanical properties, and its impact resistance and tensile strength are great among all plastics.

Based on the properties of UHMWPE raw materials, UHMWPE porous materials also have a series of characteristics that are superior to other porous materials, such as strong chemical corrosion resistance, good bio-compatibility and chemical stability, high filtration efficiency and long service life, etc., as well as good impact resistance and energy absorption capacity.

In terms of assembly, the PE porous filter element is usually assembled through interference fit. Compared with the welding of traditional micro-porous filter membrane, the technology is more simple and the cost is lower.

ePTFE sintering technology:(content to be supplemented)

ePTFE: Powder → Thermocompression (Moulding according to the mold shape to ensure homogeneous dense of the mixed powder) → Demoulding → Sintering → Finished product

For technical data sheet or application inquiry, you are more than welcome to contact our sales representative by sales@cobetterfilter.com or leave a message