Porous Filter in Pneumatic Application

Cobetter Porous PE Filter.pdf

Cobetter Porous PE Filter.pdf

When we are using industrial pneumatic equipment, the expansion and vibration of gas will produce strong noise. As one of the most efficient solutions to pneumatic noise, sintered porous silencers can let the air pass through porous sound-absorbing materials and make it rub with the materials in the silencer while flowing inside the pneumatic equipment. This process can partially convert the pressure energy of the air into heat energy and thus reduce the exhaust noise.

Cobetter porous PE silencer filter also called air muffler is sintered from ultra-high molecular weight polyethylene, which has good performance of eliminating medium frequency and high frequency noise. Porous polyethylene material is integrated with solid threaded thread, and the universal threaded connectors can fit most standard valves, ensuring that customers can easily assemble our silencers to their pneumatic equipment.

Filter Characteristics

- Light in weight, good air permeability and high corrosion resistance;

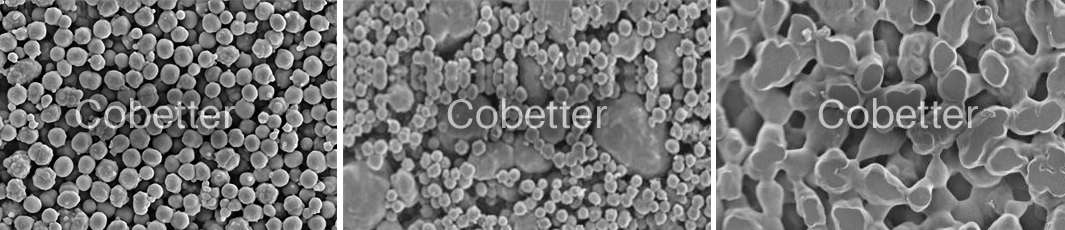

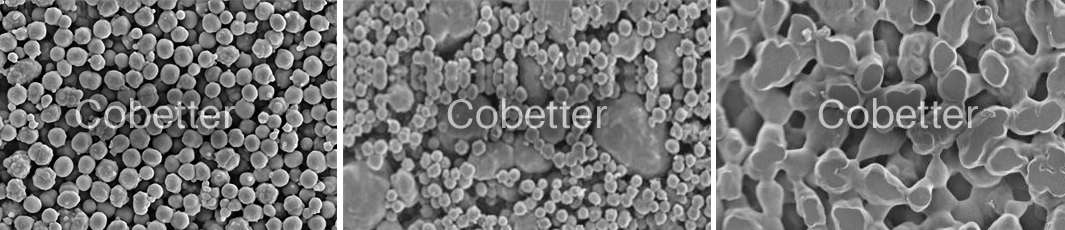

- Sintered from ultra-high molecular weight polyethylene, high porosity;

- Excellent noise reduction ability;

- Available in a variety of sizes, accept customized sizes;

- Universal M5 and NPT threaded connectors, fit most valves, convenient to assemble.

Applications

- Solenoid Valve

Cobetter sintering porous PE silencer filter can effectively reduce the pneumatic noise at the exhaust port of the solenoid valve and prevent fine particles such as dust in the environment from entering the solenoid valve, thus prolong the service life of the equipment.

- Air Compressor, Vacuum Generator

Cobetter plastic porous mufflers are usually assembled at air inlet and exhaust, which can effectively reduce the pneumatic noise of the air compressor.

For technical data sheet or application inquiry, you are more than welcome to contact our sales representative by sales@cobetterfilter.com or leave a message