Sintered Porous Polyethylene (PE) Filter

Cobetter Porous PE Filter.pdf

Cobetter Porous PE Filter.pdf

Cobetter sintered porous PE material is specially designed for specific filtration, venting , and diffusion applications.

|

|

|

| Venting | Self-Sealing | Diffusion |

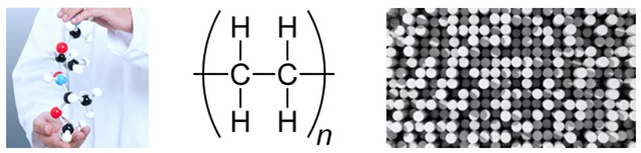

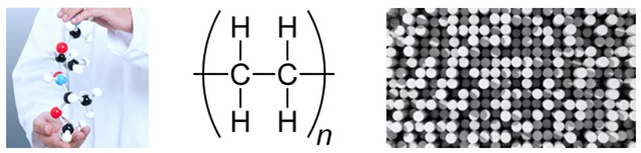

Sintering is a special process for solid material.During the manufacturing process, it was made by heating and pressing the powder material under the temperature lower than its melting point.This special method endows the material with good chemical resistance and great corrosion resistance.

The sintered PE filter has a repeating linear molecular structure -CH2-CH2, inert structure, strong molecular bonds, and stable chemical resistance. Characterized by good physical properties, light weight,good thermoplasticity, and wide pore size range from 15 to 200 um, which can be widely used in laboratory for solid-liquid filtration/separation, medical devices and drug delivery devices, automative industry, and water filtration systems.

Raw material: UPE (Ultra-high molecular Weight Polyethylene) polymer

Moreover, Self-Sealing porous plastic filter a special kind of Sintered PE filters, can be used as a design option as self-sealing vent for filtering application,it is also widely used in medical & surgical applications.

Additionally, sintering porous PE filter can be used as plastic air silencer for reducing the noise and maintain high air flow rate. This kind of porous plastic air mufflers can be applied to solenoid valve, vacuum generator, air compressor and other pneumatic equipment. Also we can provide activated carbon sintering filter with the functions of odor adsorption and water&solution purification.

Available Forms

- Sinter PE membrane

- Sinter PE plate / Polyethylene Porous Plates

- Various shapes of PE sinter porous filter in customization (i.e. plug, cylindrical)

Surface Feature

- Hydrophilic

- Hydrophobic

- Hydrophobic and self-sealing when exposed to water

Product Feature

Advantages compared with microporous membranes

A. PE sintered materials can achieve similar performance as microporous membranes, However, the process requirements for users to assemble it to the device are very low. Generally, users can seal the filter and the device by mechanical pressing and mechanical interference fit, thus, no more need for complicated and volatile welding method like ultrasonic welding, etc., which means less operational requirements on the user side. Moreover, using PE sintered material will not have the problem of static electricity during the punching process, which microporous membrane has.

Process comparison of IV Catheter

Using microporous membrane : Punching membrane - Static Elimination - Membrane Fixing - Welding - Infrared CCD Weld Inspection - Gas Inspection;

Using sintered PE simplified process : Filter Assembly - Gas Inspection

| B. Compared with other venting materials, PE sintered material has the unique advantage of self-sealing. Most of the venting materials (such as microporous membranes) have only the function of water repellent & venting, and two-way exhaust. But the self-sealing PE material will be self-sealed when contacting with water, can play functions as one way valve: |  |

Theoretical introduction of Self-sealing filters

- High porosityensures higher flow rate and lower pressure drop

- No powders or particles shedding, low extractables and leachables

- Good humidity stability

- Can be designed with two layers with two colors

- Low drug and protein adsorption

Avaliable Pore Sizes

15 - 200μm

Typical Applications

- SPE Filters / SPE Frits / Plastic Frits

- SPE Column Frits

- Dissolution Filters

- Pre-Analytic Serum Filters

- Oral Inhaler Filters

- Nebulizer Filters

- Nasal Inhaler Filters

- Vent filter for Suction Bag

- Filter plugs for dialysis solutionss

- Arterial blood collection needles

- IV Catheter blood stopper

- Hemodialysis cartridges and hemodialysis bags.

- Hydrophobic Shut-off Filter for Suction Liner Systems

- Bacteria Filter for Suction Canister

- Porous Plastic Silencer for Reducing Noise

- Sintering Filter with Activated Carbon for Wound

Life-science Lab |  |  |  |

|

Medical Devices |  |  |  |  |

|  |

|

|

| Pneumatic Devices |

To be continued ... |

|

|

|

For technical data sheet or application inquiry, you are more than welcome to contact our sales representative by sales@cobetterfilter.com or leave a message